全国服务热线:

186-1511-9565

产品展示

详细信息

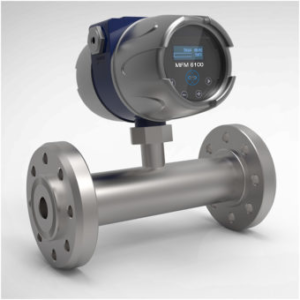

MFM 6100

Two-Phase Mass Flow Meter

The Correflow MFM combines the technology of two patented measurement techniques (velocity and concentration) in a single sensor to achieve a measurement of mass flow. The first measurement determines the two phase slurry velocity and the second measurement determines the fraction of one of the phases of the mixture in relation to the other. Combining these two parameters yields mass per unit time (ie. mass flow).

Specifications

Two Component Concentrations: 1% to 99%

Materials: Insulating liquids, solids (particulate), gas (bubbles or as carrier)

Typical Response Time: Concentration–updated at 2.5 millisecond intervals using last measured velocity; Velocity–typically updated once per second

Purge Option: Type Z purged (NEMA 4X): Cl1, Div 2, GR C&D

European (Eex approved) housing also available

Sensor: Typical Sensor Pipe sizes: 1/8” (.32 cm) ID or greater

Pressure limits: 1000 psi (69 bar) typical for small sensors, Higher pressure designs available. No moving parts, no flow restrictions or additional pressure drop

Power Requirements: 115 to 240 VAC, 50 to 60 Hz (100 Watts maximum)

Instrument air for optional pressurization(intermittently 4 scfm @ 80 to 120 psi)

Data Analysis Velocity, volume fraction, mass fraction, mass flow measurements on an instantaneous basis and averaged over user programmed time intervals, Total mass for fixed time intervals, Stream temperature

Calibration Routines: Sensor self-tuning with optional dynamic auto-zeroing routines; Adjustable gain on concentration and velocity measurement circuitry; Adjustable signal filtering on concentration measurement circuitry; Adjustable sampling rate for a wide range of process conditions

Software and fully installed PC available

Sensor connections designed intrinsically safe

Each sensor has Four 4-20mA outputs which are independently

programmable to any Four of 12 available parameters

MODBUS over RS485 or Ethernet communications: communication or data read out for remote parameter adjustment, calibration and testing.

Various digital and analog inputs optionally available

Benefits

Continuous analysis with selectable time averaging

No moving parts, unaffected by vibration

No additional pressure drop

Selectable output scaling

Designed intrinsically safe

Ruggedized for the factory environment

Instantaneous and average mass flow outputs

Non-contact measurement